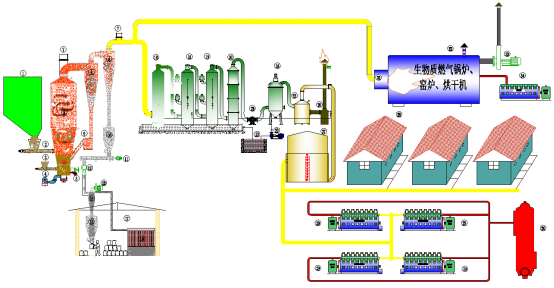

Diagram of Biomass fluidized bed gasification integrated system

1.Biomass : Saw Dust , Bamboo Chips, Straws

2.Products

2.1 Power

The biomass is fed into gasifier to be converted to Syngas ,the syngas is cooled and cleaned by cleaning system. then the syngas is piped to internal combustion gen-set to output power or sent to burn boiler to work with steam turbine.

2.2 Bio-char

a.Wood(Bamboo) Charcoal

The carbon content in Wood(Bamboo) Charcoal is 80~85%. It can be produced to activated carbon through physical method. Or it is directly used to produce “machine-made charcoal ”.

b. Straw Charcoal

The carbon content in straw charcoal is 45~50%. It can be used to produce biochar based fertilizer.

2.3Extracted Liquid

In the process of cooling and cleaning ,the extracted liquid from the gas mix with circulation water . The plant run constantly , gradually,the density of liquid is increased constantly . When the density reach the point of selling , it is sold to the fertilizer factory to produce foliar fertilizer

2.4.Thermal

The gas from gasifier can be used to burn boiler , furnace ,kilns to produce steam or supply thermal for kilns. The exhaust from engine is 550℃, it can be used to supply steam , hot water or for drying ,chilling .

2.5.Syngas

The Syngas after cooling and cleaning can be used directly by residents